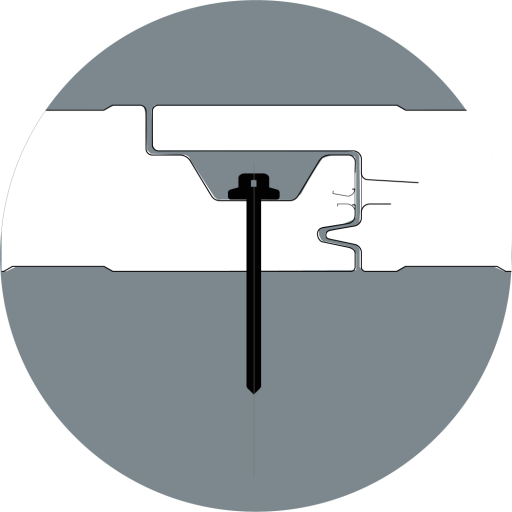

The “WALLPAP” façade panel is the ideal solution for wall cladding. It is assembled longitudinally using a tongue and groove joint system produced in the shaping machine of the continuous production line, whose design hides the screws once installed.

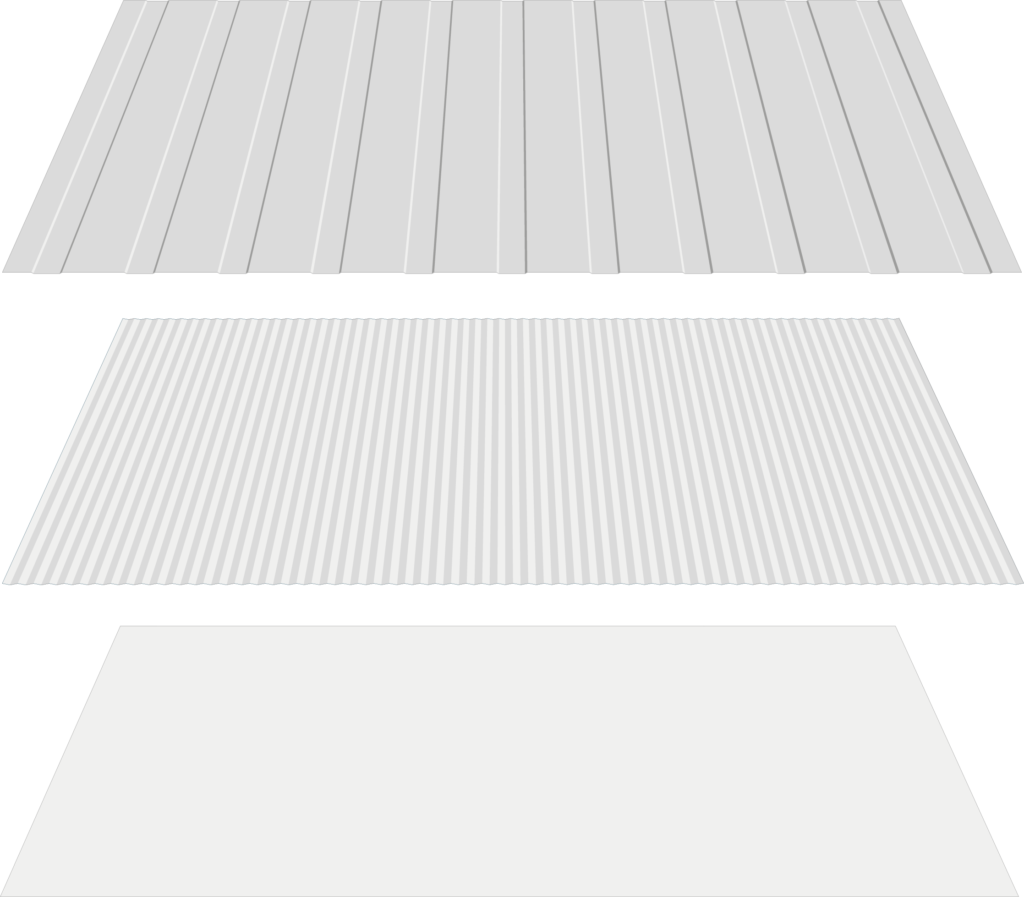

They can also be used for all kind of constructions and industrial buildings, with smooth, ribbed and micro-profiled finishes available.

PRELACQUERED GALVANISED STEEL SHEET

STANDARD COATING

FINISH OPTIONS

COLOURS

PIR (POLYISOCYANURATE)